(e.g., Heterometrus swammerdami, Heterometrus longimanus) is primarily extracted using the electrical stimulation method in a controlled laboratory setting. This technique is preferred because it yields higher quantities of purer venom without causing significant trauma to the animal, allowing for multiple extractions over time.

The general procedure involves the following

steps, performed with stringent safety measures to protect handlers from both the venom

and electric shock:

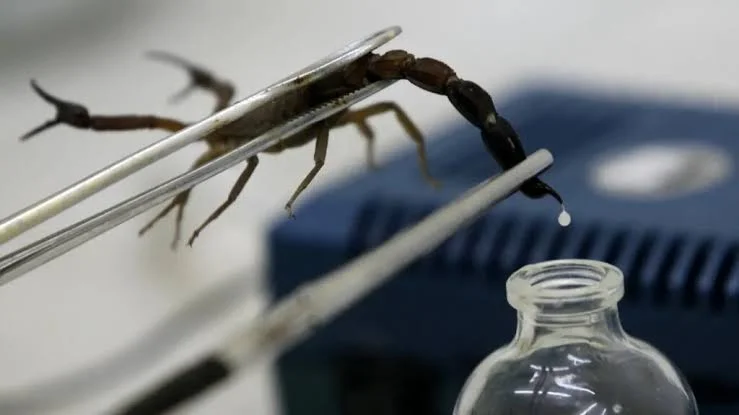

Restraint: The scorpion is placed in a specialized restraining device or held firmly

with forceps to expose the telson (stinger and venom gland). Some procedures may involve

briefly anesthetizing the scorpion with CO2 or by placing it in a refrigerator to

prevent spontaneous venom expulsion.

Electrodes connected to a low-voltage electrical stimulator (e.g., 8–12 volts, depending on the species) are applied to the tail segments, typically one next to the telson and another at the junction between tail segments IV and V.

A mild electric shock (lasting a few seconds) causes the muscles around the venom gland to contract, expelling a droplet of venom from the aculeus. The venom droplet is collected on a piece of parafilm or directly into a capillary tube or vial.

The collected venom from many scorpion is typically pooled, mixed with distilled water, and centrifuged to remove mucus and other contaminants. The resulting supernatant is then often lyophilized (freeze-dried) and stored at -20°C for long-term preservation and future use in research or antivenom production.

After extraction, the scorpion is returned to its habitat and allowed a recovery period (typically a few weeks) before the next extraction.

Venom extraction is a procedure that requires specialized training, equipment (such as robust restrainers and voltage-controlled stimulators), and strict safety protocols to prevent injury to both the handler and the animal. The process is typically conducted by trained professionals in a controlled laboratory environment or using specialized robotic milking devices designed for safety and efficiency.